Craft

Comfort & Minimal Elegance – the craft behind Atheist Shoes

Inspired by our love of the Bauhaus, and begotten of the finest leathers, we’re really happy with how our shoes have turned out and doubly delighted with the feedback they receive. Some tell us they’re “the most comfortable shoes I’ve ever owned”. One customer said, “it’s like walking on hugs from baby kittens!” And we're happy that people of all ages and walks of life appreciate the way they look.

So we wanted to share the thinking behind our shoes – why they are the way they are, what makes them so comfy, and how we make them.

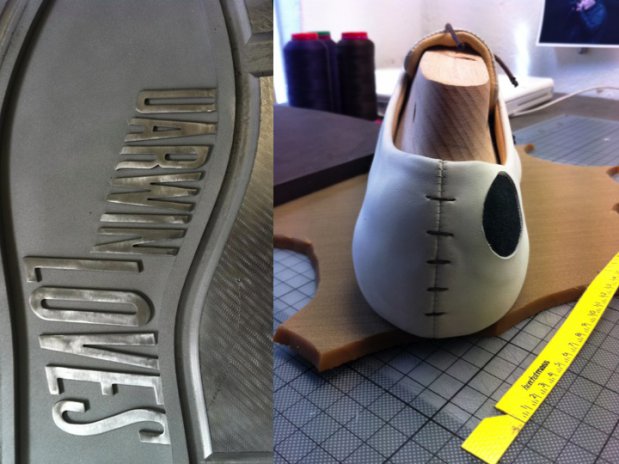

(our very first shoe)

Our classic shoes & boots

Atheist shoes are designed in Berlin and handmade by a small team of shoemakers in Portugal. It was important to us to keep all parts of the process in Europe, where working conditions are excellent, everyone involved is fairly paid and the origins of all materials known.

The design is aesthetically minimalist, as we try to stay faithful to Bauhaus principles. We use as few pieces of leather as we can - just 3 pieces of upper leather, whereas most shoemaking uses 10 pieces plus*. The shoe is an exercise in “form-through-function”, with the last having been inspired by the shape of a real human foot, which is surprisingly rare in last design. And the shape of the shoe comes directly from this last, with a slightly rounded toe and slender heel.

The shape lends a great deal to the comfort of the shoe. But so does the leather we use – Nubuck, Napa, Pull-up waxed leather, and stupendously silky full calfskin lining – all natural and unprocessed, only vegetable dyed and gently tumbled for added softness. Despite that softness, these leathers are as robust as any, and will keep your feet warm and dry in the winter, and cool and airy in the summer.

When we started out, we fell in love with these leathers. Yet we were told they were “too good to be used in shoes”, that their quality wouldn’t be appreciated. Well, we’re happy to use the best materials we can find and our customers think it’s been worth it.

The soles of our shoes are made from a natural rubber, which is hard-wearing yet comfy, and EVA cushioning beneath the heel. Their attachment to the upper is secured by a traditional "blake stitch", and a leather midsole lies at the core of the shoe.

The unique message on the underside of our shoes is created with a metal mould. It was important in our design that we keep the sole very slight and entirely beneath the upper - far too many shoes and sneakers have soles that creep up around the edges, in an unattractive "cup" and we were keen to restore a more traditional, pre-war method for bonding sole and upper.

Our Goodyear Welted boots

Our latest new venture is Goodyear Welted Boots. They have the same uppers as our classic boots, but the sole is a complete departure; a leather midsole, combined with Vibram's most classic rubber sole - the Carramoto - and consummated with a Goodyear welt for strength, durability and ease of sole replacement.

Why have we done this? After years of having no heel on our boots, it's fun to finally try one. And so many customers have asked for a proper "Winter Boot", so it's time we give it a go.

Goodyear welt construction" involves stitching the upper leather, lining leather and welt (a specially prepared strip of leather) to the ribbing that has already been bonded to the insole as an attach-point for the midsole and outsole. The space enclosed by the welt is then filled with cork (for breathability and cushioning), and the leather outsole is both cemented and stitched to the welt, before the rubber outsole is cemented to the leather outsole. The final stitch is between the welt and the outsole, a stitch that can be cut through enabling complete removal of the sole without causing damage to the upper.